Dehydration problem in the freezing of IQF berries: why and how to face it

Product dehydration during the freezing process is a crucial aspect due to its direct impact on product quality and weight. This makes dehydration (loss of water) one of the biggest issues that food processors deal with as it leads to a decrease in their yield and profitability. However, it also poses a big challenge to the suppliers of freezing solutions.

The problem can become even more critical when it comes to berries, as they contain between 85 and 92% water. Thus, it is essential for food processors to understand how product dehydration works. By gaining a full understanding, processors can have better control of the process, minimizing profit loss without damaging the quality of the product.

How does production dehydration occur?

During the freezing process, the product is exposed to low-temperature airflow. The difference in humidity between the product and this air causes moisture loss, which is released through the membranes of the product.

Several factors are involved in the freezing process and can lead to dehydration. First is the freezing time, which should be as short as possible in order to achieve a rapid crust freezing that would immediately lock the moisture inside the product. Second is the aerodynamics created inside the freezer which is determined by temperature, air pressure, airspeed, and humidity. It is essential to control these values to avoid the formation of snow, which is, in fact, a direct indicator of high levels of dehydration.

Since a freezer is a closed environment, the moisture that precipitates into snow can only come from the product, which will occur when the relative humidity of the air reaches its saturation point. This, together with low air velocity and the wrong temperature and air pressure, facilitates the formation of the ice nucleus, a particle that functions as a nucleus for the formation of an ice crystal and contributes to snow formation.

How to achieve low dehydration with OctoFrost IQF Freezer?

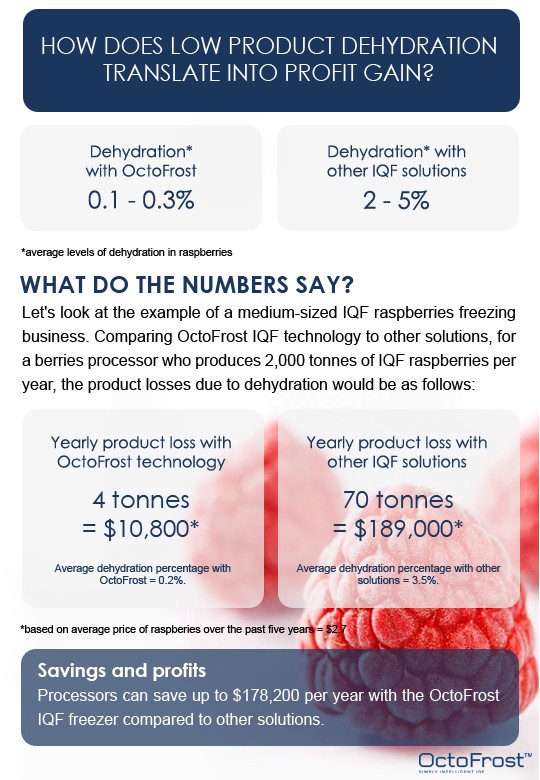

OctoFrost customers report that the dehydration levels of their products range on average between 0.1 and 0.3%, depending on the type of product being frozen. In contrast, other solutions on the market reach between 2 and 5%. This is due to the OctoFrost IQF freezer’s adjustable fan speed, which creates unique aerodynamics for each type of product.

This means that each application is processed under the optimal and required combination of airspeed, air pressure, and relative humidity. With the right balance of continuous airflow and airspeed, dehydration is reduced to a minimum.

Premium berries with low dehydration levels

Since berries are composed of a high percentage of water, it is crucial for food processors to control water loss, as it would seriously affect their quality, appearance, and weight. Customers claim that fluidized freezing is significantly more efficient than static freezing when it comes to processing berries, as it does not compromise on quality and allows a larger quantity to be processed in a shorter time.

Given that too much airflow would provoke a loss of moisture and a too low one would slow down the freezing time, the challenge is to optimize the settings of airflow and speed. Thanks to the adjustable airflow of the OctoFrost IQF Freezer, optimal conditions can be met for each type of berry, thus achieving energy efficiency and higher yield.

En

En  Укр

Укр

_large.png)